A practical example of a life cycle assessment

A life cycle assessment can be complex but with the example outlined below, we hope to make this simple and easy. Getting insights into your products footprint can actually be quite fun. You will spot loads of opportunities to innovate along the way.

What is a life cycle assessment?

A life cylce assessment is a method to calculate and understand the environmental impact of product, service or process throughout its entire life cycle. This includes the extraction of raw materials, manufacturing, transportation, usage, and disposal or recycling. By assessing these stages, LCA helps in understanding the complete environmental impact of a product or process and identifies areas for improvement in terms of sustainability, it allows you to quantify the environmental impacts of products or services and find ways to reduce them.

-

Is there a lower-carbon feedstock you could choose?

-

Are you powering your production process via renewables? What is your electricityy, water and overall energy usage during production.

-

Can you use a more sustainable material for your packaging?

-

How can you optimise your logistics? Are you using an electric fleet?

-

What is your by-product volume? Can you switch to compostable packaging or a more circulair product?

Where to start your LCA?

Starting a Life Cycle Assessment (LCA) is a journey into understanding the environmental footprint of a product or service. It begins with setting clear intentions - what's the focus of your study, and what do you hope to achieve? Whether it's enhancing sustainability or trimming down carbon emissions, your goal guides the process.

Next, consider the scope and what functional unit you will report on. Here, you’ll also paint a picture of the product's life from cradle to grave, cradle to gate or cradle to cradle.

Data collection

Data collection is the next vital step. Best way is to draw out the full production process and the product life cycle into a flow chart. Per phase, you can easily what data needs to be collected. Start gathering information on raw materials, energy use, emissions, waste - the full environmental impact. This stage demands attention to detail and thoroughness and will require you to connect with other departments and suppliers.

When gathering data for a life cycle inventory, you might get lucky and find exactly what you need straight from the supplier or your own research. But if that's not the case, no worries! There are plenty of databases out there filled with secondary data – things like industry averages or findings from scientific studies – ready to help fill in the gaps.

Primary Data

This refers to data that is collected firsthand by the researcher. It's original and specific to the particular study or project. In an LCA, primary data could be the direct measurements of energy usage, waste generation, or emissions from a specific manufacturing process. This data is often more accurate and relevant to the specific context of your study, but it can be more costly and time-consuming to gather.

VS

Secondary Data

This is data that has already been collected and published by someone else. It could include industry averages, data from scientific literature, or government reports. In an LCA, secondary data might involve general emissions factors for transportation, average energy usage data for a certain type of manufacturing process, or waste generation rates from similar products. Secondary data is usually more accessible and less expensive to obtain, but it might not be as precise or tailored to the specific case you're studying.

Secondary is most likely easier to find but less detailed vs primairy data. It’s all about balancing these two. If the balance is off, no worries, make sure to set out a plan and milestones to get there; continues improvement.

Example; A golf ball LCA

1. Raw Material Extraction: Golf balls are typically made from various materials like rubber, resin, and sometimes a urethane cover. The extraction of these materials involves processing petroleum products and natural rubber, which can have environmental impacts such as habitat disruption and pollution from extraction processes.

2. Manufacturing: This stage involves the transformation of raw materials into the core and cover of the golf ball, along with the application of any coatings or paints. Energy is consumed during the manufacturing process, and emissions, including volatile organic compounds (VOCs) from paints and coatings, can be a concern.

3. Transportation: After manufacturing, golf balls are distributed worldwide. This involves shipping, either by road, sea, or air, contributing to the product's carbon footprint through fossil fuel consumption and greenhouse gas emissions.

4. Usage: The environmental impact during the usage phase of a golf ball is relatively low in terms of energy or material consumption. However, lost golf balls can become an environmental concern, especially if they end up in natural habitats like forests, lakes, or oceans.

5. End-of-Life: Golf balls can end up in landfills, where their non-biodegradable materials can last for a very long time. Some golf balls are recycled or refurbished, which lessens their environmental impact but is not yet a widespread practice.

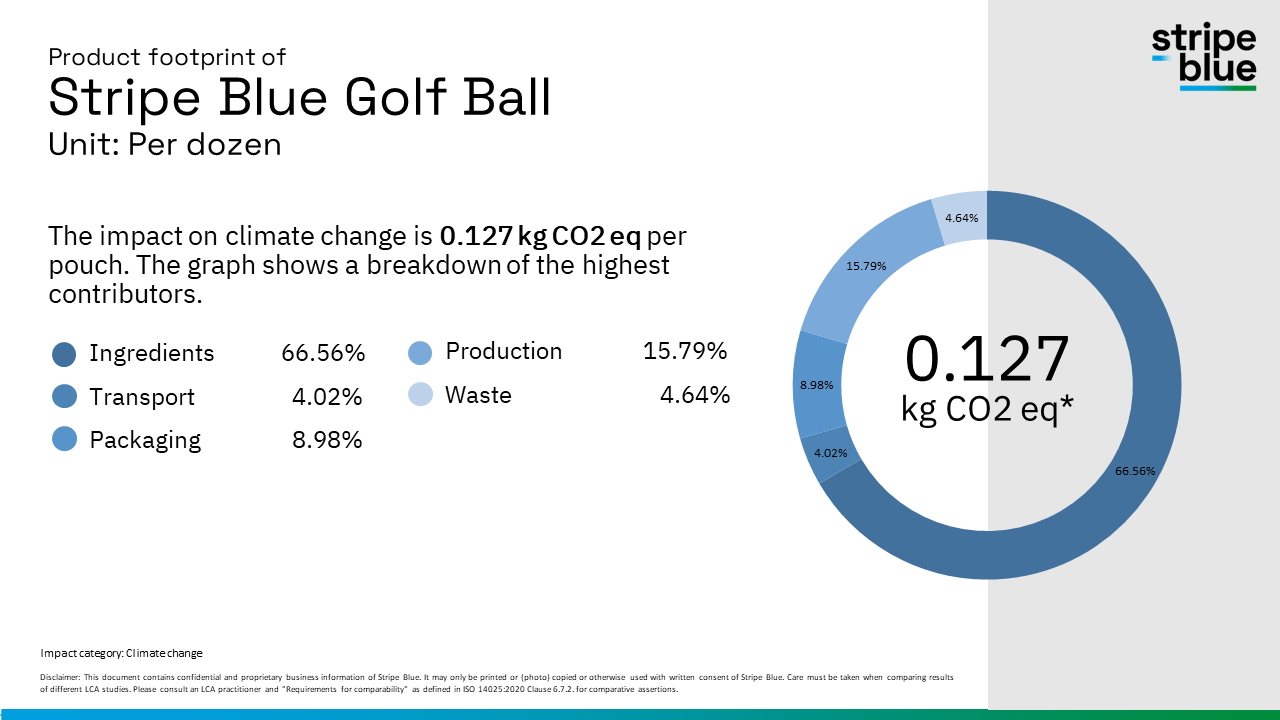

The environmental product declaration

The LCA is completed and we have a clear picture of the impact of every step and component. Often this contains detailed and confidential data that you dont want to share publically. An Environmental Product Declaration is often used instead. An EPD is based on the data obtained from the LCA and goes a step further by presenting this information in a standardized, easily understandable format. Something you can share on your website and with your customers. It will support and reinforce your sustainability messaging. Below our golf ball EDP!

How we can help?

We have LCA’s experts inhouse that can support you and get you on your way.

LCA experts inhouse

Familiar with these tools and understand pro’s and con’s depending on your use case

Industry specific know how on newest innovations that will enable you to reduce your footprint